Browse Tough Surface: Why Picking the Right Undercarriage Parts Issues

Wiki Article

Maximize Efficiency With Durable Undercarriage Components

In the realm of hefty machinery and tools, the function of undercarriage parts is paramount in making sure optimal efficiency and longevity. The effectiveness and effectiveness of these parts can substantially influence the total operation of machinery, making the option of resilient undercarriage components an important choice for operators and supervisors alike. By exploring the intricate relationship in between longevity and performance in undercarriage parts, a much deeper understanding of the subject arises, clarifying the crucial aspects that drive functional success. As we browse with the complexities of undercarriage element, maintenance, and durability selection, a thorough expedition waits for to reveal the crucial methods for attaining peak efficiency in durable applications.Advantages of Using Durable Undercarriage Components

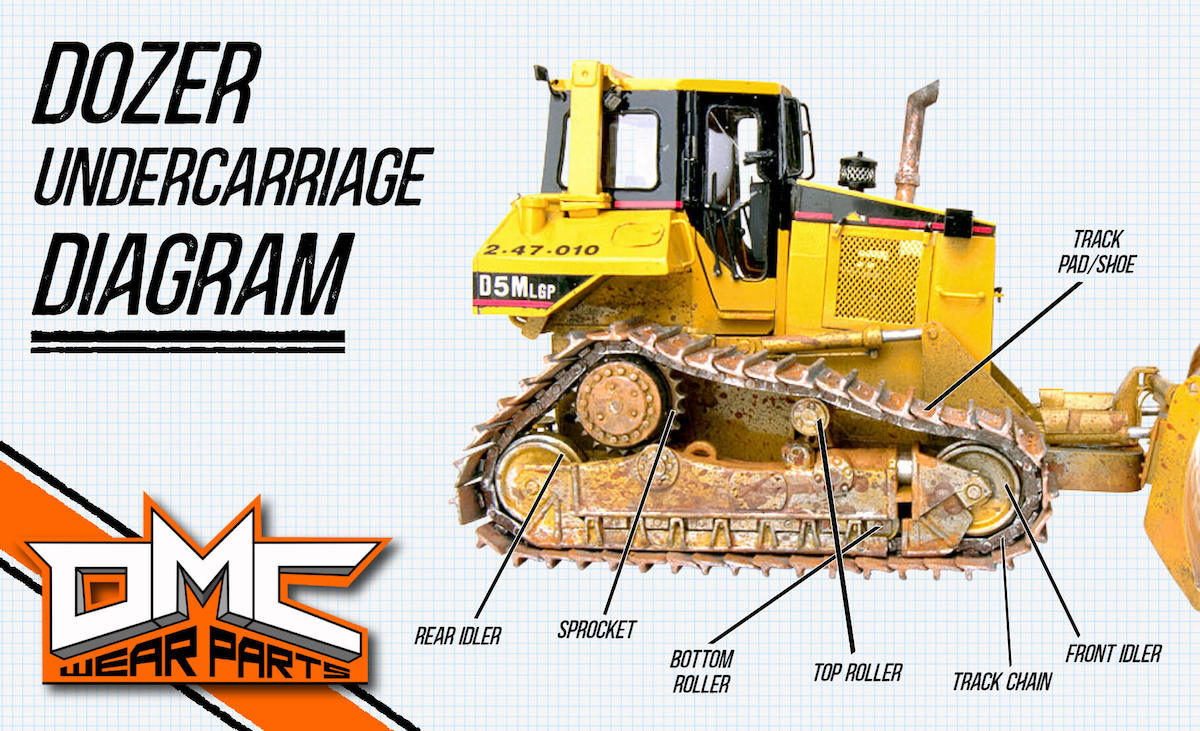

Making use of durable undercarriage parts not only boosts the longevity of hefty equipment yet also decreases maintenance prices considerably. By purchasing high-quality undercarriage elements, such as tracks, rollers, idlers, and gears, tools operators can experience raised uptime and improved total efficiency.

Additionally, the long life of heavy equipment is straight linked to the top quality of its undercarriage components. Sturdy parts can withstand the rigors of demanding applications, guaranteeing that the devices stays functional for extensive durations. Because of this, drivers can prevent pricey downtime and upkeep expenditures, inevitably optimizing the roi for their equipment.

Elements Influencing Undercarriage Toughness

The sturdiness of undercarriage parts in heavy machinery is affected by different essential elements that directly effect performance and durability. Premium materials, such as hardened steel, are essential for enduring the extreme problems and heavy loads that undercarriage components are subjected to - undercarriage parts.Additionally, ecological elements can have a significant effect on the durability of undercarriage parts. Direct exposure to abrasive products, severe temperatures, and severe working conditions can increase deterioration on undercarriage elements. As a result, selecting undercarriage components that are particularly designed to hold up against these environmental challenges is crucial for guaranteeing sturdiness.

In addition, the design and engineering of undercarriage parts have a straight influence on their sturdiness. Components that are developed to disperse lots evenly, minimize rubbing, and decrease anxiety concentrations are more probable to have a much longer life expectancy - undercarriage parts. By thinking about these essential variables, devices drivers can make the most of the toughness and efficiency of their undercarriage elements

Maintenance Tips for Lengthening Undercarriage Life

Applying normal maintenance routines is essential for prolonging the life expectancy of undercarriage components in hefty machinery. Additionally, guarantee that the undercarriage is effectively lubed according to producer standards to minimize friction and protect against premature wear.An additional essential maintenance suggestion is to maintain the undercarriage tidy from dirt, rocks, and particles. Accumulation in the undercarriage can accelerate wear and deterioration, resulting in pricey repair services. Washing the undercarriage after procedure in extreme conditions is advised to stop these issues.

Last but not least, tracking and recording maintenance tasks can aid in producing a proactive upkeep timetable. Keeping detailed records of replacements, repair services, and assessments can give valuable understandings into the undercarriage's condition and efficiency with time, aiding in anticipating and protecting against potential failings. By adhering to these upkeep tips faithfully, drivers can substantially enhance the resilience and efficiency of undercarriage parts in hefty equipment.

Picking the Right Undercarriage Components

Choosing suitable undercarriage elements is essential for maximizing the efficiency and long life of heavy equipment. When it comes to selecting the right undercarriage parts, there are several variables to take into consideration.Choosing for reputable brand names understood for generating high-performance and sturdy undercarriage components can dramatically impact the total effectiveness and long life of the equipment. By very carefully choosing the best undercarriage parts, devices proprietors can enhance performance, minimize downtime, and extend the life-span of their heavy equipment.

Study: Improved Efficiency With Sturdy Components

Including long lasting undercarriage components has demonstrated significant enhancements in equipment efficiency. One situation research included a building and Recommended Site construction firm that updated its excavator's undercarriage components to much more long lasting options. The business observed a significant reduction in downtime because of undercarriage upkeep, causing increased productivity and cost savings. The resilient components held up against extreme working problems, minimizing deterioration significantly.In one more circumstances, a mining operation changed the undercarriage parts of its excavator with premium, resilient choices. This switch resulted in an impressive enhancement in the bulldozer's ability to move and overall efficiency. The machine can navigate tough terrains a lot more successfully, bring about enhanced operational effectiveness and lowered fuel usage.

In addition, a logging firm invested in resilient undercarriage components for its forestry tools. The updated components exhibited extended life-span and increased resistance to abrasion from rough terrain. The company experienced minimized upkeep costs and enhanced devices uptime, inevitably increasing its bottom line. These study emphasize the substantial advantages of making use of resilient undercarriage components in maximizing equipment performance and durability.

Conclusion

To conclude, making use of long lasting undercarriage parts can considerably improve efficiency and durability of heavy equipment. Aspects such as appropriate upkeep and picking the best components play an important role in making best use of undercarriage longevity. By applying these methods, services can decrease downtime, rise performance, and eventually save money on operational costs. Instance research studies have revealed that investing in long lasting he has a good point undercarriage components can bring about company website boosted total efficiency and efficiency in different industries.The performance and efficiency of these parts can substantially influence the total operation of equipment, making the selection of long lasting undercarriage parts a crucial choice for managers and drivers alike.Including resilient undercarriage components has shown significant improvements in machinery performance. These instance studies highlight the substantial benefits of making use of resilient undercarriage parts in enhancing machinery efficiency and long life.

In conclusion, using long lasting undercarriage components can significantly enhance efficiency and long life of hefty equipment (undercarriage parts). Instance studies have shown that spending in sturdy undercarriage parts can lead to improved general performance and efficiency in different industries

Report this wiki page